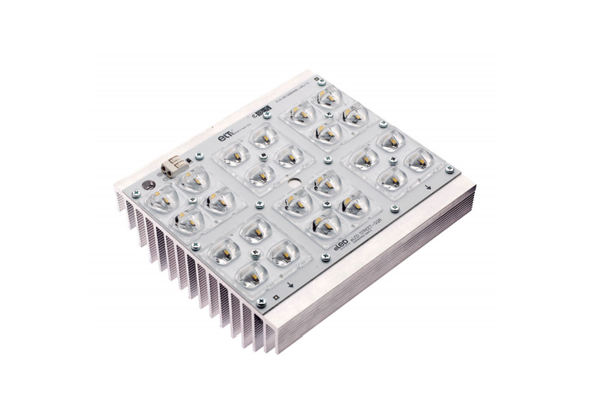

According to a fact sheet from LightingAssociates.org, magnetic ballasts sold after 1990 bear the designation “energy-saving” and are about eight percent more efficient than older ballasts.

Meanwhile, electronic ballasts use a variety of electronic components to convert the lamp operating frequency from 50Hz to 20-40Hz. The high frequency operation reduces internal losses in the lamp and conserves energy.

While a lot of manufacturers are switching to electronic ballasts, this does not mean that magnetic ballasts are a thing of the past. Electronic ballasts are good, but a lot of people still choose to go old school and buy high quality magnetic ballasts because they last longer, and at times are more economical than electronic ballasts.

In a nutshell, here is how ballasts work. A fluorescent lamp passes an arc of electricity from one end of the lamp to the other in order to produce light. The arc interacts with mercury vapour producing radiant energy. When this energy hits the phosphor coating on the inside of the lamp, the phosphor gives off light. Once the arc is established, only a low voltage is required to maintain it since a high voltage will burn out the lamp in a short span of time. The role of a ballast is to initially provide a high starting voltage, then afterwards limits the amount of current in the lamp.

If your facility is operational more than eight hours a day, it may be cost-effective to replace standard ballasts with energy-saving magnetic ballasts.

Energy-saving magnetic ballasts are simply improved versions of the standard ballasts. Standard ballasts contain aluminum while the new magnetic ballasts contain copper wire coils and the iron cores are larger. The copper has lower resistance and the larger iron core produces less heat inside the ballast, which both result to efficiency improvements, thereby making it more eco-friendly.

Additional source: http://www.energydepot.com/RPUcom/library/LIGHT001.asp